CRACK LUMINESCENCE (RILUMINATI)

Product features:

- Reliable, early and passive method for detecting fatigue cracks

- Long-term monitoring in critical areas

- No information about the crack location required

- Testing under UV light

- Possibility of automated crack detection (remote monitoring) during ongoing processes

- Excellent adhesion to metal surfaces thanks to the combination of elasticity and strength

- Suitable for industrial applications on metal surfaces

- High UV resistance

- Color strength and shine are retained for a long time

- Processing temperature -10 to +80°C

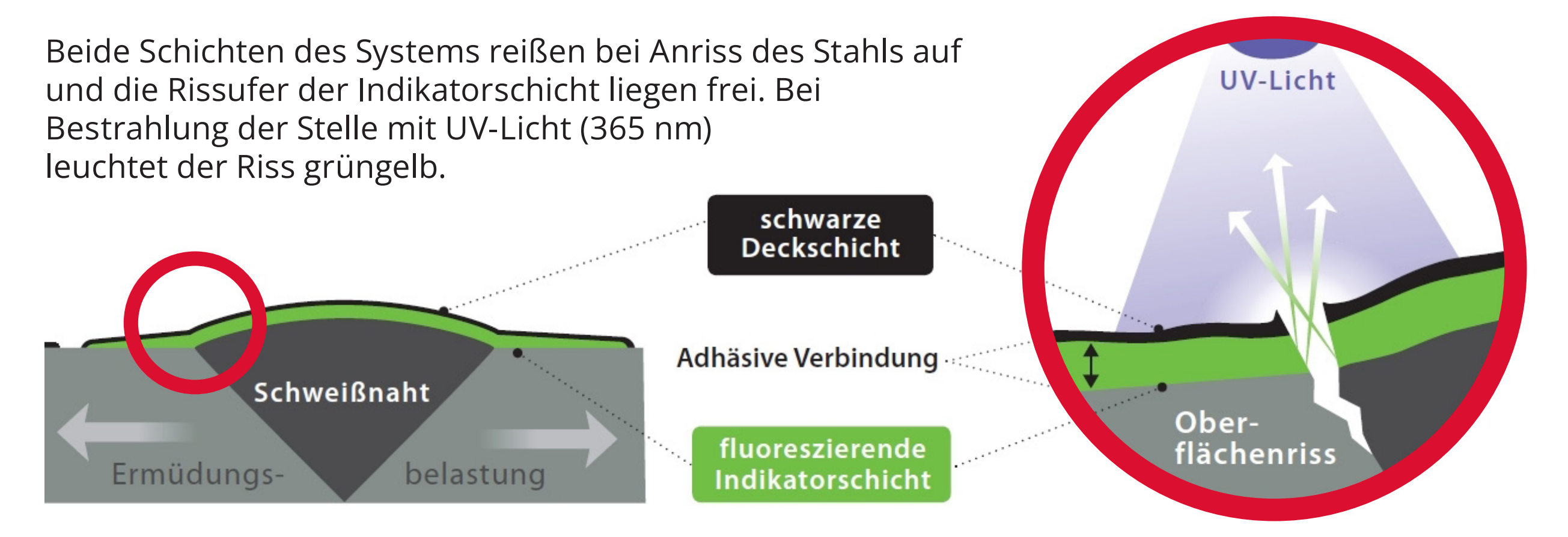

FUNCTIONAL PRINCIPLE

- RILUMINATI 815 emits light as fluorescence under UV light. This makes it possible to recognize the resulting crack

- RILUMINATI 816 covers the indicator layer and at the same time prevents the indicator layer from radiating in order to achieve the highest possible contrast between the crack and the indicator layer

Both layers of the system tear open when the metal cracks and the crack edges of the indicator layer are exposed. When the area is irradiated with UV light (wavelength 365 nm), the crack fluoresces yellow-green.

GENERAL NOTES

Contaminants such as rust, scale, paint, oil and grease must be removed from the surface to be tested in order to achieve the best possible adhesion. Shake the aerosol can well before use. When using the packaged product, stir the container well. The use of RILUMINATI 815 and RILUMINATI 816 in the aerosol can is simple and uncomplicated. Spray onto the dry and grease-free surface from a distance of 20 cm. The coats should be sprayed on quickly, without interruption, in a zigzag pattern to achieve a perfect result. The spray can should not be held at too much of an angle when spraying in order to avoid spray overspray. The product can be applied by spraying or rolling. Commercially available spraying equipment and paint rollers for industrial use can be used for this purpose.

The advantages of the RILUMINATI

- Low effort for the user due to one-time coating and large-area testing

- Uncomplicated application without specialist knowledge (visual inspection)

- Remote monitoring possible, cracks can be detected with the naked eye or surveillance camera

- Monitoring possible during the running process

- Even areas that are difficult to access