Dolphicam2 is a revolutionary platform for non-destructive ultrasonic testing.

The system supports a wide range of high-resolution imagers for multi-material inspections.

- Schedule a no-obligation demonstration

- Free advice & always personal contact

- Replacement devices for repairsDevice training possible

- Incoming and outgoing quality controls according to ISO:9001

The dolphicam2 MAUT platform can be used for a wide range of materials and NDT applications. One of the main strengths of the dolphicam2 is the composites industry (carbon and glass fibers) where defects such as impact damage, delamination and porosity are inspected in aerospace, automotive and wind energy. The technology is also used in metallic applications such as corrosion in pipes and tanks, crack detection, adhesive bonding, etc.

DESCRIPTION

The unique probe technology and powerful design generate high-resolution ultrasonic images of areas suspected of damage. It helps manufacturing and service personnel to perform effective and reliable non-destructive testing to check the condition of the material.

The system’s impressive performance generates live images in real time. This results in an improved user experience and a high probability of detection. Live streaming of full matrix datasets enables, among other things, advanced post-processing and total focusing, reducing the minimum defect detectability to 1/10 mm in some cases!

Through our FTD (Flexible Transducer Development) process, we can customize transducers based on specific customer materials and other requirements. New transducers in combination with optimized signal processing, ultrasonic technology and modified user interfaces can be delivered within a few weeks.

The Dolphicam2 can be ordered as a turnkey system with a Panasonic Toughpad Windows tablet. The system supports 1 or 2 simultaneous transducers, 1-2 encoders, Ethernet, GPIO, Wi-Fi and Bluetooth. An open and well-documented API and open file formats allow third-party providers to control the Dolphicam2 and access live images and data sets for further analysis.

Dolphitech technology is accepted by leading customers in the automotive and aerospace industries, including Airbus, Boeing, Audi and Lamborghini.

Your advantages:

- Dry/adjusted coupling

- 2D and 3D images

- Large area stitching

- 1 or 2 transducers

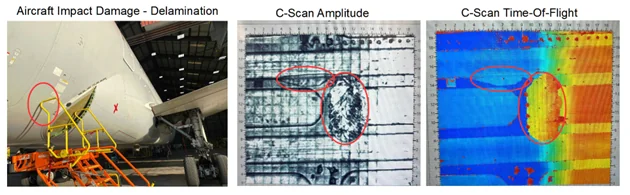

Figure 6: Impacted Composite Aircraft Boeing 787 (Dreamliner)

C-scan Images show that fuselage is disbanded from stringer frame

Figure 7: Corrosion on Aluminum Alloy from Aircraft

C-scan Images show corrosion with detailed depth information

YOU MIGHT ALSO BE INTERESTED IN

The Danatronics UPG-07 Color series is available in 4 models

The probe is specially insulated in accordance with the requirements of ATEX, Zone 3.